Making red bricks at home can be a rewarding experience, offering cost savings, creative customization, and the satisfaction of building something from scratch. Whether you’re looking to build a garden wall, patio, or small shed, mastering the art of making homemade bricks can be an invaluable skill.

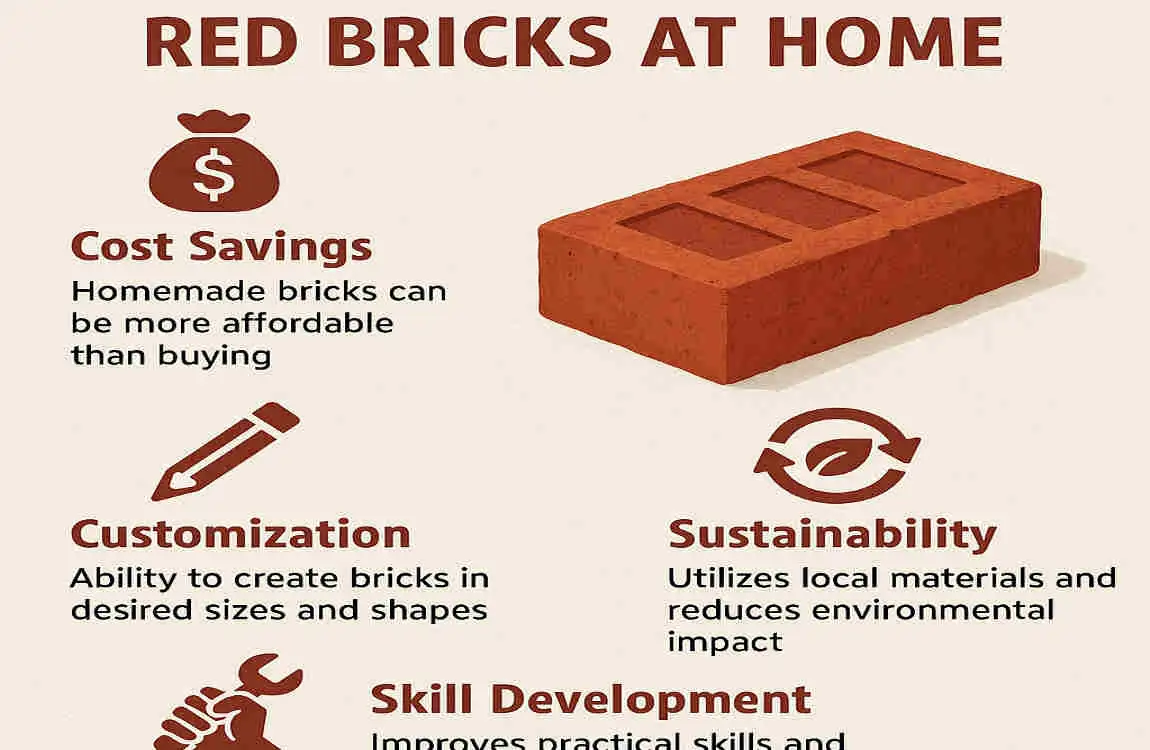

Benefits of Making Red Bricks at Home

Cost Savings

One of the most significant advantages of homemade red bricks is the cost. Store-bought bricks can be expensive, especially for large-scale projects. By making them at home, you can save up to 70% on material costs. All you need is some clay, sand, and a few basic tools.

Customization

When you make your own bricks, you have complete control over their size, shape, and even color. This makes it easier to tailor the bricks to your specific project, whether it’s a rustic garden wall or a sleek patio.

Sustainability

Homemade bricks are eco-friendly. By using locally sourced clay and reducing transportation emissions, you’re making a more sustainable choice. Plus, you can reuse materials like straw or dryer lint as binders, reducing waste.

Skill-Building

Making red bricks is not just a practical skill—it’s a stepping stone to larger construction projects. Once you’ve mastered this process, you can take on bigger tasks like building sheds, outdoor ovens, or even tiny homes.

Materials and Tools Needed

Creating homemade red bricks requires a few materials and tools. Most of these items are easily accessible, and some you may already have at home.

Materials

Here’s a list of essentials for making around 100 bricks:

- Red Clay Soil: Approximately 50-100 lbs of clay. Test the soil’s plasticity to ensure it’s suitable for brick-making.

- Sand or Dryer Lint: About 20% of the mix. This helps improve the strength and reduce cracking.

- Water: Use sparingly to achieve a dough-like consistency.

- Straw (Optional): Acts as a natural binder and adds durability.

Tools

- Brick Molds: Wooden or PVC molds, typically 4x8x2 inches, for shaping the bricks.

- Tamper or Block of Wood: Used to compress the clay mixture into molds.

- Wheelbarrow or Large Mixing Tray: For mixing clay, sand, and water.

- Shaded Drying Area: To air-dry the bricks before firing.

- Kiln or DIY Pit: For firing the bricks at high temperatures.

Sourcing Tips

- Finding Clay: You can dig clay from your backyard or nearby areas. Avoid contaminated soil or clay with too much organic matter.

- Local Suppliers: Check local hardware stores or construction suppliers for materials like sand or straw.

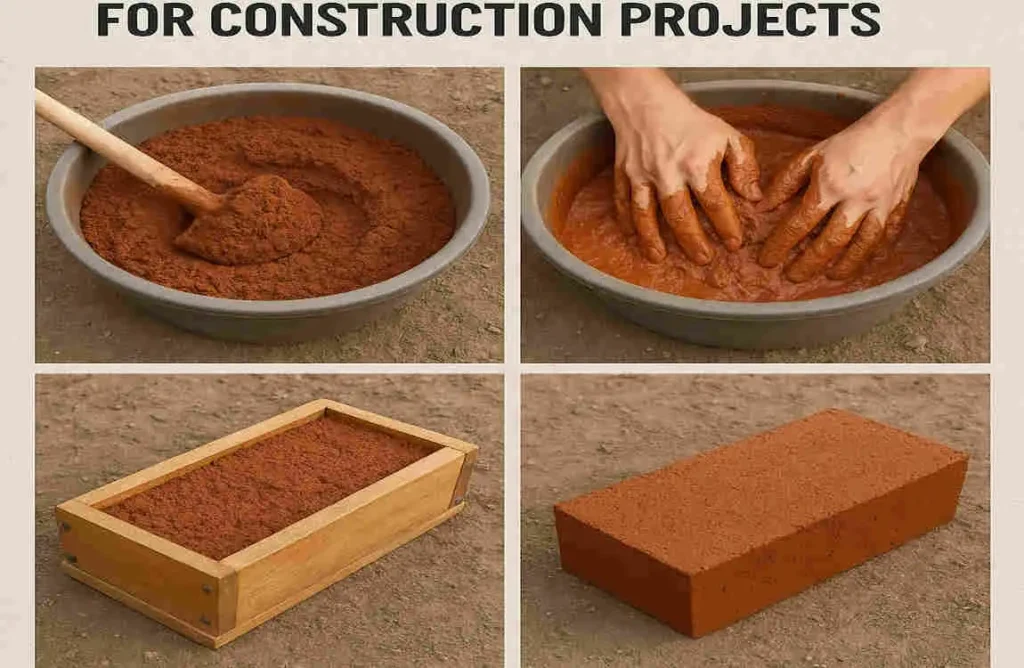

Step-by-Step Guide: How to Make Red Bricks at Home

Making red bricks at home involves several stages, from preparing the clay to firing the final product. Let’s break it down step by step.

Preparing the Clay Mixture

The quality of your bricks depends heavily on the clay mixture. Follow these steps to prepare it properly:

- Test the Soil:

- Take a handful of clay soil and roll it into a sausage shape. If it holds its form without cracking, it’s suitable for brick-making.

- If it crumbles or cracks, mix in more clay or water until you achieve the right consistency.

- Mix the Ingredients:

- Combine 70% clay, 20% sand, and 10% water or straw in a wheelbarrow or large tray.

- Knead the mixture thoroughly until it feels like dough. This step ensures even distribution of materials and removes air pockets.

- Check the Consistency:

- The mixture should hold its shape when pressed into a ball but not stick to your hands. Adjust by adding more sand (if sticky) or water (if too dry).

DIY Mold Construction

If you don’t have ready-made molds, you can easily create your own. Here’s how:

- Materials for Molds:

- Use wooden planks or PVC sheets to build molds. The standard brick size is 4x8x2 inches, but you can adjust it based on your needs.

- Assembly:

- Cut and assemble the pieces into rectangular frames. Secure them with screws or nails to ensure durability.

- Tips for Better Molding:

- Coat the inside of the molds with oil or a non-stick spray before pressing in the clay mixture. This makes demolding easier.

Forming the Bricks

Now that your clay is ready and molds are prepared, it’s time to shape the bricks.

- Filling the Molds:

- Press the clay mixture firmly into the molds. Use a tamper or a block of wood to ensure there are no air pockets.

- Overfill slightly, then scrape off the excess with a flat edge for a smooth surface.

- Demolding:

- Gently lift the molds to release the shaped bricks onto a shaded drying board.

- Be careful not to damage the soft bricks during this process.

Drying Process

Drying the bricks is a crucial step to prevent warping or cracking during firing.

- Air Drying:

- Place the bricks in a shaded area with good airflow. Avoid direct sunlight, which can cause uneven drying.

- Turn the bricks daily for 3-7 days to ensure even drying.

Firing for Strength

Firing the bricks hardens them and gives them their characteristic red color.

- Build a DIY Kiln:

- Construct a simple kiln using old bricks or dig a pit in the ground. Arrange the bricks to allow airflow.

- Firing Process:

- Heat the kiln to approximately 900°C (1650°F). Maintain this temperature for 24-48 hours.

- Allow the kiln to cool completely before removing the bricks.

Common Mistakes and Troubleshooting

Even with careful preparation, mistakes can happen. Here are some common issues and how to fix them:

Cracking During Drying

- Cause: The mixture is too wet or lacks enough sand.

- Solution: Adjust the clay-to-sand ratio and ensure proper kneading.

Weak Bricks After Firing

- Cause: Inadequate firing temperature or time.

- Solution: Use a thermometer to monitor the kiln temperature and extend the firing duration if needed.

Warping

- Cause: Uneven drying or poor handling.

- Solution: Turn bricks daily and handle them gently.

Using Homemade Red Bricks in Construction Projects

Once your bricks are ready, there are countless ways to use them in construction. Here are a few ideas:

Garden Walls

- Stack the bricks using a 1:4 cement-sand mortar mix for stability.

- Add decorative patterns for a unique touch.

Patios or Outdoor Ovens

- Use a running bond pattern for patios or pizza ovens. This ensures strength and even weight distribution.

Tiny Structures

- Build small sheds, storage units, or animal shelters. Reinforce the corners with additional mortar for durability.

Safety, Legal, and Scaling Tips

When making bricks at home, ensure safety and compliance with local regulations:

- Safety Precautions:

- Wear gloves and a mask to avoid contact with dust and chemicals.

- Ensure proper ventilation during the firing process.

- Legal Considerations:

- Check local building codes before using homemade bricks for permanent structures.

- Scaling Up:

- Invest in larger molds and better firing equipment if you want to produce bricks on a commercial scale.